Engineering Services

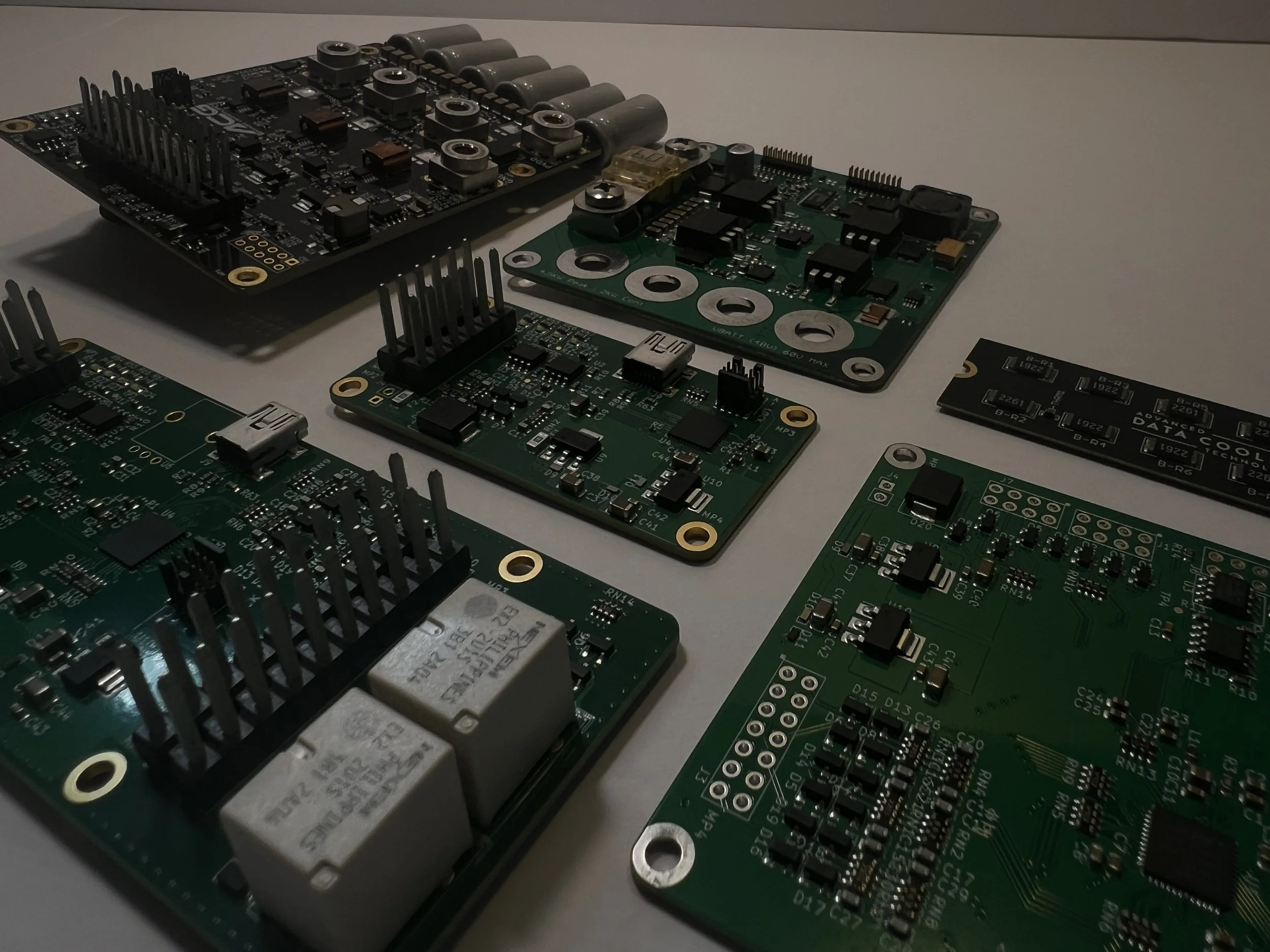

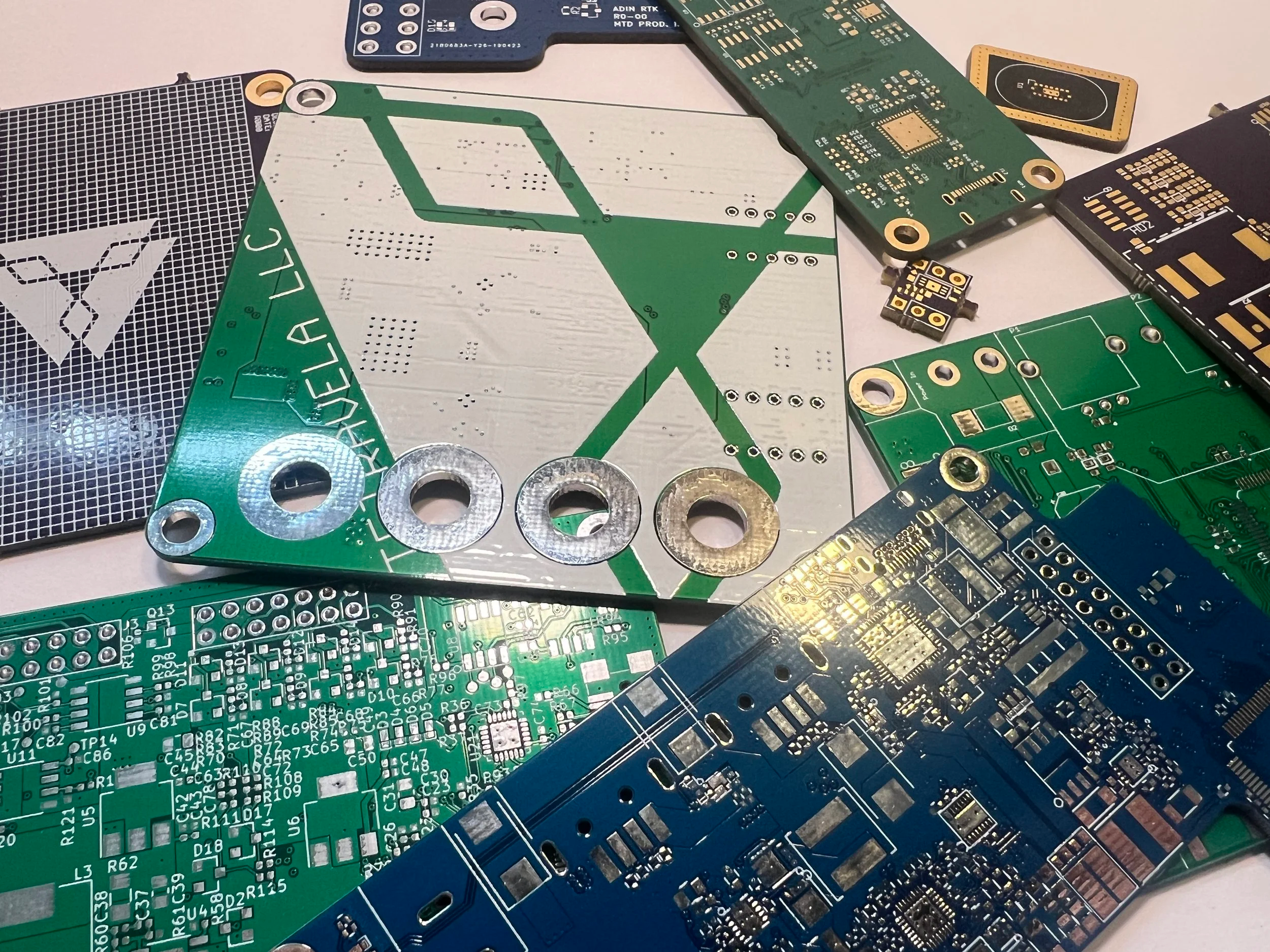

PCB Design and fabrication

The majority of Tetravela’s projects consist of at least one custom PCB. These are typically embedded circuits with a microcontroller running custom firmware.

We are continually pushing ourselves with new challenges of ultra-small formfactors or high performance to cost/size ratios.

Software development

Tetravela offers expert knowledge in both software and firmware development. C/C++ code written for a variety of microcontroller platforms. We have direct experience with most communication protocols including CAN-FD, parallel interfaces, and MIPI DSI.

We also have experience with embedded GUI via graphics libraries (Touch GFX, emWin).

Tetravela has a strong background in brushless motor control and advanced position and speed control topologies for high performance circuits.

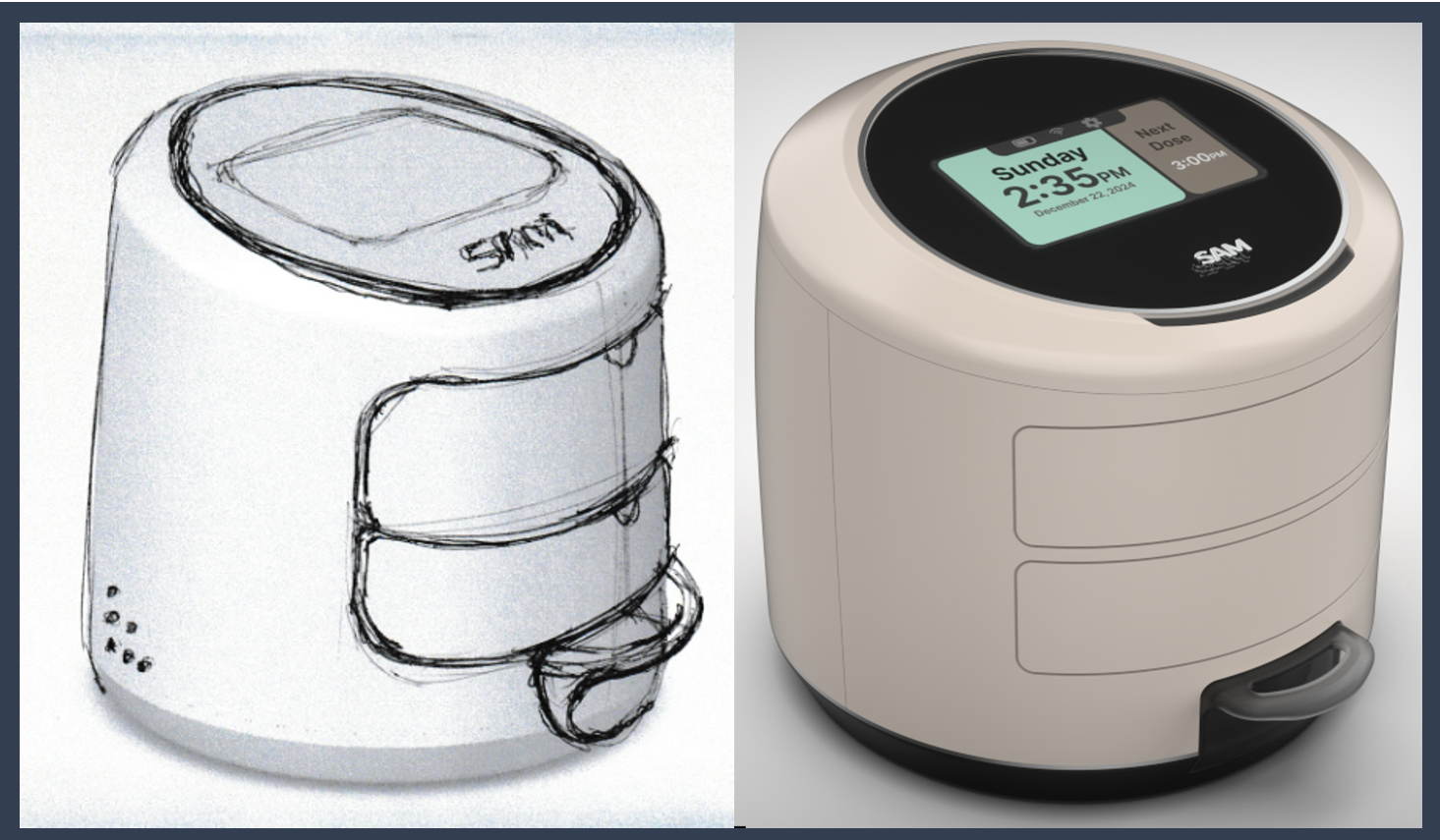

industrial design

Humans are remarkably visual creatures. A compelling product need not only function well, but should also be comfortable to use, and have looks that excite and inspire. Tetravela can take your product or concept to the next level with a comprehensive overhaul that captures all requirements and essence and delivers the vision and aesthetic you aim for.

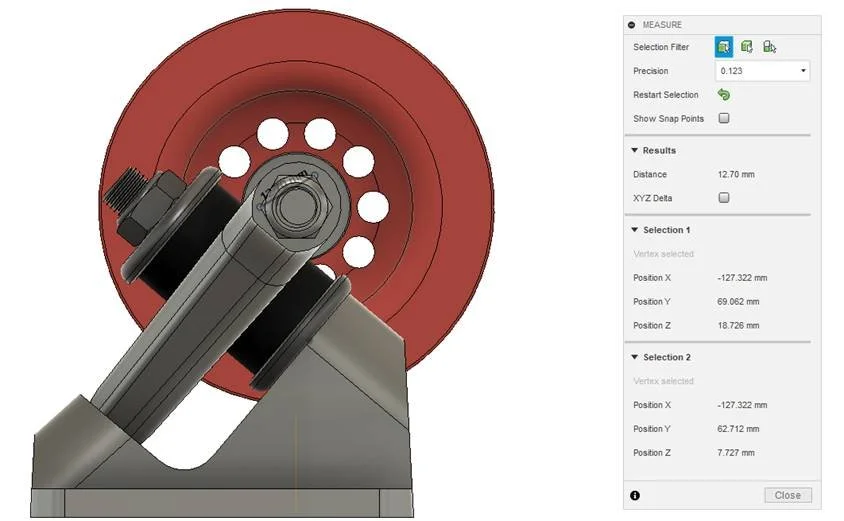

mechanical engineering

From injection molded components that snap together without fastners, to gearboxes where efficiency and longevity matter. Unsure if your design will perform how you need it to? Not sure where to start? Tetravela can provide the right set of eyes on your project to make sure all performance metrics are met.

testing

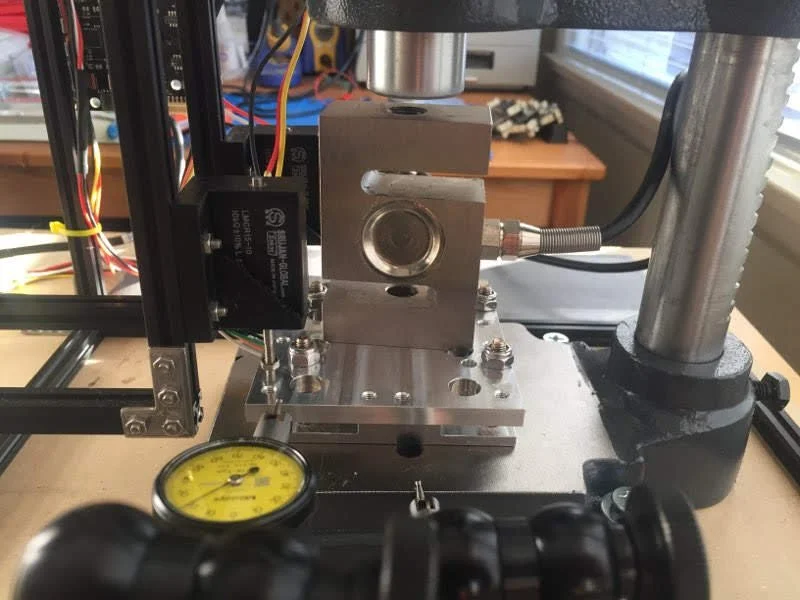

Building your prototype isn’t even half of the work when it comes to market launch. Extensive testing is required to eliminate issues from new designs and product concepts and quickly and early as possible. Tetravela is able to build a small test fleet for accelerated parallel test hour accumulation. We are also capable of designing and implementing automated test fixtures for 24/7 testing with data acquisition.

documentation

Many startups and small businesses struggle with allocating resources for documentation. However, it is an essential piece to any engineering endeavor.

Other Services

FABRICATION

Tetravela has partnered with a state of the art metal fabricator. With a high capacity facility and advanced equipment your most ambitious components, assemblies, and creations can be brought to life.

A metal laser with 1” thickness capacity, formed metal, hand welding, robotic welding, and other custom fabrication can be integrated with our core services.

SOURCING

Tetravela employs a large network of partners to deliver a variety of components and materials to its customers.

Some materials include:

machined metal components

3d prints

injection molding

custom silicone

wiring harnesses

glass display and lenses

Content Generation

Tetravela can create a variety of media for your promotional and technical needs.

Photos and videos of prototypes including edited multi-shot demonstration videos

realistic 3d renderings and animations from CAD files

blog and social media posts

other technical documentation and literature

PROTOTYPE FLEET AND SMALL BATCH MANUFACTURING

Once your design is ready for a larger batch build, we can help make that a reality rapidly. Let us be your provider for your next build.